PDR (Paintless Dent Repair) for steel panels is a popular automotive body repair method due to its numerous advantages over traditional welding or painting techniques. It's faster, more cost-effective, and preserves the original paint finish, thereby increasing vehicle resale value. The growing demand for non-destructive repairs and quick turnarounds has driven shops to invest in specialized PDR equipment and training, making it a game-changer in the auto body repair industry. As an eco-friendly solution, PDR is increasingly favored by both collision centers and car owners seeking high-quality bumper repair and body restoration.

In today’s automotive landscape, Professional Detailing Repair (PDR) for steel panels is a game-changer. This non-invasive technique offers numerous advantages, from preserving original factory finishes to significantly reducing repair costs compared to traditional methods. As a result, more shops are specializing in PDR for steel panels, catering to the growing demand for efficient, cost-effective, and high-quality repairs. This article explores the benefits of PDR, the rise of specialized shops, and its future impact on the automotive repair industry.

- The Advantages of PDR for Steel Panels

- Why Specialized Shops are on the Rise

- The Future of Repairs: PDR's Impact and Benefits

The Advantages of PDR for Steel Panels

PDR for steel panels offers a multitude of advantages that make it a preferred choice for many automotive body shops. Firstly, it’s an efficient process that significantly reduces repair time compared to traditional methods like welding or painting. This not only benefits the shop by increasing productivity but also ensures faster turnaround times for customers. Secondly, PDR is highly cost-effective as it minimizes material waste and labor costs associated with more invasive repairs.

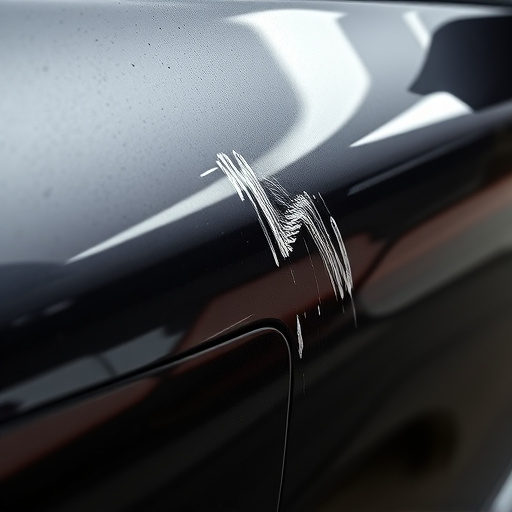

Moreover, PDR results in minimal to no paint damage during the repair process, preserving the original finish of the steel panel. This aesthetic advantage enhances the overall value of the vehicle. In contrast to car dent repair methods that might leave permanent marks or require extensive painting, PDR for steel panels offers a delicate touch, making it ideal for maintaining the car’s resale value. Therefore, many car body shops are specializing in this technique to cater to customers seeking high-quality, swift, and cost-efficient repairs.

Why Specialized Shops are on the Rise

In recent years, there’s been a notable trend among shops specializing in PDR for steel panels. This shift is driven by several key factors. Firstly, the growing demand for precise, non-destructive repair methods has led many car body shops to invest in specialized equipment and training for PDR. Unlike traditional bumper repair or car body restoration methods, PDR offers a cost-effective and efficient solution for minor dents and dings on steel panels, without requiring extensive painting or replacement.

Additionally, the rise of specialized shops caters to the increasing preference for quick turnarounds and high-quality finishes. By focusing exclusively on PDR for steel panels, these shops can offer more streamlined services, reducing wait times and ensuring customer satisfaction. This niche specialization also allows them to stay ahead of industry trends, continually updating their techniques and tools to meet the evolving needs of vehicle owners looking for top-notch bumper repair and car body restoration.

The Future of Repairs: PDR's Impact and Benefits

The future of repairs is here, and it’s all about PDR for steel panels. This innovative technique has revolutionized the auto body repair industry, offering a faster, more cost-effective solution for damage to vehicle exteriors, particularly on steel panels. As the demand for efficient and eco-friendly vehicle collision repair continues to grow, PDR stands out as a game-changer.

By specializing in PDR, shops are able to provide significant benefits to their customers, including reduced repair times, minimal paint disruption, and preservation of the original factory finish. This not only saves time and money but also ensures that vehicles return to the road with a like-new appearance. As the world shifts towards more sustainable practices, the advantages of PDR become even more evident, making it a preferred choice for both collision repair centers and car owners seeking top-notch, modern auto body repair solutions.

PDR (Paintless Dent Repair) has emerged as a game-changer in the automotive repair industry, particularly for steel panels. Its advantages are clear: minimal damage, faster repair times, and cost-effectiveness. As a result, more specialized shops are focusing on PDR for steel panels, meeting the growing demand for efficient and high-quality repairs. Looking ahead, PDR’s impact is expected to continue to grow, revolutionizing how we address dents and scratches on steel surfaces, and ensuring a brighter, smoother future for vehicle aesthetics.