Paintless Dent Repair (PDR) equipment is crucial for modern car body shops, enabling technicians to remove dents and scratches without traditional paint removal. This method saves time and costs while preserving the vehicle's original finish. Both new and experienced professionals need to understand diverse PDR tools, their uses, and best practices to ensure high-quality auto body services. Staying updated with technological advancements in PDR equipment is essential for maintaining competitiveness in the industry.

“Unleashing the power of Paintless Dent Repair (PDR) equipment? This comprehensive guide is your ultimate resource for mastering both beginner and advanced safety techniques. As PDR gains popularity, ensuring proper handling of specialized tools is crucial. From understanding the diverse range of PDR equipment to implementing safety measures, this article equips you with knowledge. Beginners will navigate safe practices, while experts will discover advanced tips for risk mitigation and equipment maintenance, ensuring a secure and efficient dent repair journey.”

- Understanding PDR Equipment and Its Importance

- – Definition of Paintless Dent Repair (PDR) and its growing popularity

- – Overview of various PDR tools and equipment used in the industry

Understanding PDR Equipment and Its Importance

PDR equipment plays a pivotal role in both car body shop and auto body services operations. It refers to the specialized tools and technology used for paintless dent repair, allowing technicians to remove dents and scratches from vehicle surfaces without sandpaper or paint removal. Understanding PDR equipment is crucial for anyone involved in auto repair services, as it offers numerous benefits over traditional dent repair methods.

This modern approach not only conserves the original factory finish of a vehicle but also saves time and reduces costs. For beginners, investing time to learn about different types of PDR tools, their functions, and proper usage is essential for achieving consistent results. Experts, meanwhile, should stay updated on the latest advancements in PDR technology to enhance their skills and provide superior auto body services.

– Definition of Paintless Dent Repair (PDR) and its growing popularity

Paintless Dent Repair (PDR) is a cutting-edge technique that’s transforming the automotive care industry. By using specialized tools and skilled techniques, PDR allows for the repair of dents, dings, and creases in vehicle bodies without the need for traditional painting or bodywork. This non-invasive method has gained immense popularity due to its cost-effectiveness, speed, and ability to preserve the original factory finish. The growing demand for eco-friendly and efficient vehicle maintenance has further fueled the adoption of PDR, making it a preferred choice for both personal and commercial tire services and vehicle restoration projects.

With its precision requirements, PDR demands investment in quality PDR equipment. Skilled technicians leverage these tools to delicately work on tight spaces and complex shapes, ensuring flawless fender repair outcomes. As the industry continues to evolve, advanced PDR equipment is becoming more accessible, empowering both beginners and experts to offer top-notch services that cater to modern car owners’ needs for quick, efficient, and aesthetically pleasing vehicle repairs, including fender repair solutions.

– Overview of various PDR tools and equipment used in the industry

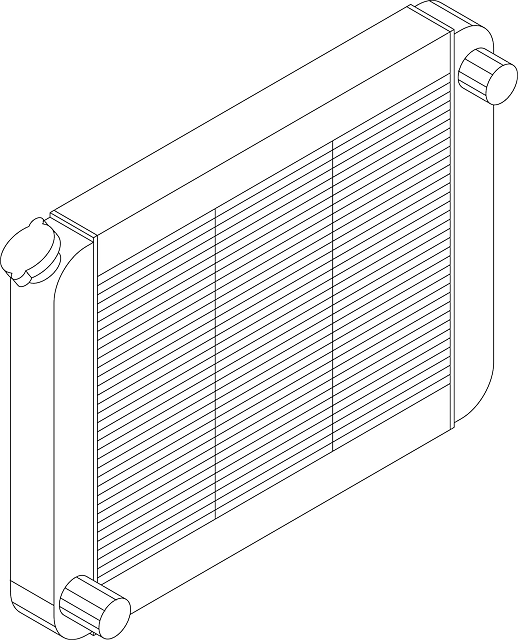

In the realm of automotive aesthetics, Paintless Damage Repair (PDR) has emerged as a game-changer, revolutionizing car damage repair techniques. PDR equipment encompasses a diverse array of tools designed to rejuvenate vehicles’ exterior without resorting to intensive auto painting or frame straightening processes. These innovative devices range from specialized mallets and picks for removing dents, to sophisticated air compressors and thermal guns for reshaping metal. The beauty of PDR lies in its versatility; it caters to both beginners seeking a simple way to fix minor dents and experts looking for precise, efficient solutions.

For instance, PDR professionals often employ handheld tools capable of manipulating metal with incredible accuracy, ensuring minimal disruption to the car’s surface. Additionally, modern technology has given rise to advanced equipment such as LED lights for improved visibility during intricate repairs and digital sensors that precisely measure and monitor temperature during thermal healing processes. These advancements in PDR equipment not only enhance repair quality but also streamline the overall auto painting process, making it a preferred choice for those aiming to preserve their vehicle’s original finish while achieving flawless results.

Whether you’re a seasoned professional or just starting out in Paintless Dent Repair (PDR), prioritizing safety with your equipment is paramount. Always remember to inspect tools for damage, wear proper personal protective equipment (PPE), and follow manufacturer guidelines for use and maintenance. By adhering to these simple yet crucial PDR equipment safety tips, you’ll not only ensure your well-being but also maintain the quality and reputation of your work.