In flexible bumper repair, using high-quality, genuine or certified replacement parts specific to your vehicle is crucial for optimal results. Modern bumpers often require specialized adhesives and repair kits tailored to their composite structure, featuring impact-resistant plastics, polymer compounds, and rubber elements. Proper preparation, including cleaning, decontaminating, and priming the damaged area, ensures lasting adhesion during repairs, from simple cracks to complex dent removal. Skilled technicians inspect damage, employ advanced tools & techniques, and restore both aesthetics and structural soundness through precise, tailored kits for successful flexible bumper repair.

In today’s digital era, a flawless flexible bumper repair is more crucial than ever for both aesthetics and safety. This comprehensive guide unveils the secrets to achieving top-notch results. We’ll walk you through selecting the finest materials – compatible with your vehicle’s make and model, even from original equipment manufacturers (OEMs). Next, we master the repair process, offering a step-by-step approach with tips on alignment, tools, and minimizing damage. Finally, we ensure longevity through aftercare, curing processes, regular maintenance, and knowing when professional touch-ups are necessary.

- Choosing the Right Materials for Optimal Results

- – Selecting high-quality parts and materials

- – Compatibility with your vehicle's make and model

Choosing the Right Materials for Optimal Results

When undertaking a flexible bumper repair, selecting the right materials is paramount to achieving optimal results. This involves choosing high-quality replacement parts that are specifically designed for your vehicle’s make and model. Using genuine or certified substitutes ensures compatibility and longevity. Moreover, consider the material composition; modern flexible bumpers often require specialized adhesives and repair kits tailored for their composite structure.

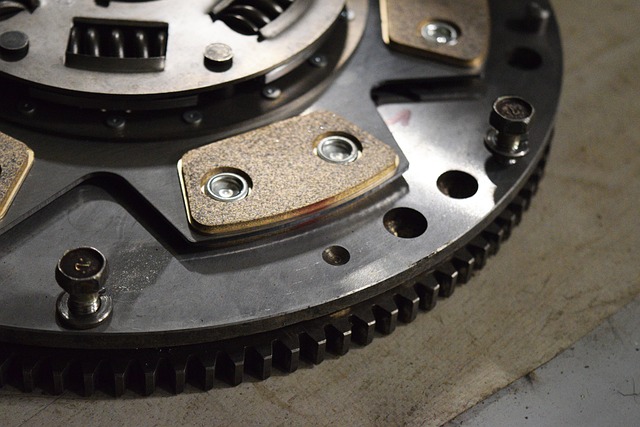

Auto body shops proficient in flexible bumper repair should stock a range of suitable materials. This includes impact-resistant plastics, advanced polymer compounds, and resilient rubber elements. Proper preparation of the damaged area is crucial before applying these materials. Skilled technicians will meticulously clean, decontaminate, and prime the surface to guarantee lasting adhesion during the auto body repair process, be it a simple crack or a more complex dent removal.

– Selecting high-quality parts and materials

When undertaking a flexible bumper repair, prioritizing high-quality parts is paramount for achieving optimal results. Opting for genuine or certified replacement components ensures they meet the exact specifications of your vehicle, promoting a seamless fit and structural integrity. These parts are designed to withstand routine wear and tear, offering durability that can match or even exceed the original equipment. Moreover, using top-tier materials such as impact-resistant plastics and robust metal alloys enhances the bumper’s ability to absorb and dissipate energy during a collision, enhancing safety features built into your vehicle.

Selecting high-quality parts for flexible bumper repair goes hand in hand with meticulous preparation. Skilled technicians should thoroughly inspect the damaged area, identifying the extent of the dent or crack. This step is crucial as it dictates the type and quantity of materials needed for effective repairs. Additionally, using advanced tools and techniques, such as precision dent removal methods, ensures that any imperfections are eliminated, leaving a flawless finish that restores both the bumper’s aesthetic appeal and structural soundness—an essential aspect in the broader context of car body restoration.

– Compatibility with your vehicle's make and model

When considering a flexible bumper repair, one of the primary factors to ensure quality results is compatibility with your vehicle’s make and model. Not all bumpers are created equal, and using a repair kit that isn’t tailored to your specific car can lead to subpar results or even further damage. A compatible repair solution will precisely match the contours and dimensions of your bumper, ensuring a seamless fit both aesthetically and functionally.

Proper compatibility goes beyond just the physical dimensions. It also encompasses the material composition and finish of your bumper. Different vehicles use varying materials, from plastic to fiberglass to metal, each requiring distinct repair techniques and products. Choosing an auto detailing kit designed specifically for your vehicle’s make and model guarantees that you’re using the right tools and materials from the outset, setting the stage for a successful flexible bumper repair at a reputable collision center.

Ensuring quality in a flexible bumper repair involves a meticulous approach. By choosing the right materials, specifically high-quality parts compatible with your vehicle, you set the stage for optimal results. This attention to detail not only guarantees a durable fix but also preserves the aesthetic appeal of your car. For an effective and reliable solution, prioritizing the right components is key in the realm of flexible bumper repair.