Streamlining paintless dent repair (PDR) time is key in today's automotive industry. By analyzing each stage of PDR, using advanced tools like CAD software and robotic systems, and standardizing techniques with uniform protocols, shops can significantly reduce repair times while maintaining quality standards, benefiting both technicians and customers alike.

The field of paintless dent repair (PDR) is constantly evolving, and optimizing repair times is a key focus for professionals aiming to meet growing demands. This article delves into strategic approaches to enhance PDR efficiency, exploring three critical areas: evaluating current processes, leveraging technology, and standardization. By implementing these strategies, PDR technicians can significantly reduce turnaround times, ensuring faster service and enhanced customer satisfaction in today’s competitive market.

- Evaluating Current Paintless Dent Repair Processes

- Leveraging Technology for Time Efficiency

- Standardizing Techniques to Reduce Turnaround Times

Evaluating Current Paintless Dent Repair Processes

The current state of paintless dent repair (PDR) practices is a key area to explore as we look towards optimizing time. PDR has evolved significantly in recent years, offering efficient solutions for vehicle body repair, especially in the luxury vehicle market where precision and speed are paramount. However, there’s always room for improvement when it comes to paintless dent repair time.

By evaluating existing processes, professionals can identify bottlenecks that hinder efficiency. This involves scrutinizing each step of the PDR process, from initial assessment and tool selection to technique application and final touch-ups. Understanding how these factors impact paintless dent repair time is crucial in designing strategies for optimization, ensuring not just speed but also maintaining the high standards expected in automotive restoration.

Leveraging Technology for Time Efficiency

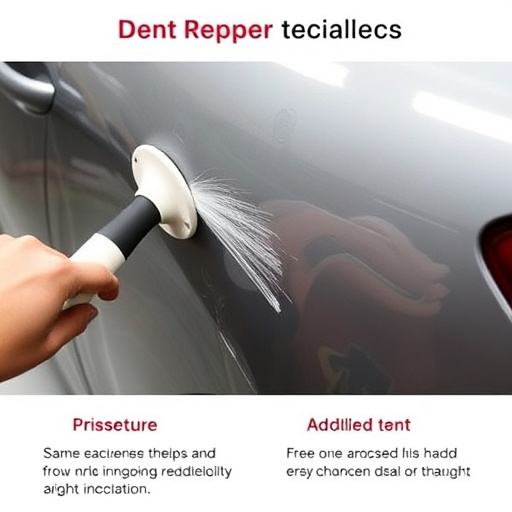

In today’s fast-paced world, every minute counts, especially when it comes to optimizing the paintless dent repair time in automotive collision repair and car restoration processes. Technology plays a pivotal role in revolutionizing how we approach these delicate tasks. Advanced tools designed specifically for paintless dent removal have emerged, offering significant advantages over traditional methods. These innovative solutions not only enhance efficiency but also ensure precision and quality. By leveraging computer-aided design (CAD) software and digital measurement tools, technicians can accurately assess and repair dents faster, reducing overall job completion time.

Additionally, the integration of robotic systems and automated equipment in automotive restoration processes streamlines various stages, from dent detection to final smoothing. These technologies enable more consistent and repeatable results, minimizing human error and the time required for manual adjustments. As a result, customers benefit from quicker turnaround times without compromising on the meticulous craftsmanship that defines car restoration projects.

Standardizing Techniques to Reduce Turnaround Times

Standardizing techniques across the board can significantly reduce paintless dent repair time. By establishing uniform protocols and training all technicians on these methods, auto body repairs become more efficient. This involves learning and implementing specific tools, tactics, and technologies designed to streamline the process without compromising quality. Standardized procedures ensure that every dent is assessed and treated in a consistent manner, minimizing the time spent on each job.

Additionally, focusing on car scratch repair and fender bender scenarios with an optimized approach can further cut down turnaround times. Pre-set protocols for these common issues allow technicians to quickly assess and begin repairs, reducing wait times for customers. This systematic efficiency ensures that shops offering paintless dent repair services stay competitive while delivering top-quality auto body repairs.

The journey towards optimizing paintless dent repair (PDR) time involves a combination of process evaluation, technology adoption, and standardized techniques. By leveraging these strategies, PDR professionals can significantly reduce turnaround times, enhancing customer satisfaction and operational efficiency. As the demand for swift yet quality repairs grows, staying ahead with innovative practices will be key to success in this competitive industry.