PDR for steel panels offers a transformative approach to auto repair, realigning damaged areas without sanding or repainting, preserving the original finish. Ideal for minor to significant impacts, PDR is on-site, swift, precise, and eco-friendly compared to traditional methods. Technicians match exact colors for seamless finishes, restoring vehicles to pre-incident condition with minimal environmental impact, as evidenced by satisfied customer reviews.

“Discover the transformative power of PDR (Panel Damage Repair) in revolutionizing steel panel restoration. This innovative technique offers a cost-effective and efficient solution for damaged or dented steel surfaces. In this article, we explore the myriad benefits of PDR for steel panels, including enhanced aesthetics and increased durability. Through real-world customer testimonials, we showcase the successful outcomes of PDR, proving its effectiveness in various industries. Learn how this game-changing method can restore your steel panels to their original condition.”

- Understanding PDR: A Revolutionary Panel Restoration Technique

- Benefits of Using PDR for Steel Panels

- Real-World Success Stories: Customer Testimonials Unveiled

Understanding PDR: A Revolutionary Panel Restoration Technique

PDR, or Paintless Damage Repair, is a cutting-edge technique revolutionizing the way steel panels are restored. Unlike traditional collision damage repair methods that often involve sanding and repainting, PDR uses specialized tools to gently push and pull damaged areas back into place, effectively removing dents and dings without impacting the surrounding panel surface. This non-invasive approach not only preserves the original factory finish but also reduces the time and labor required for repairs, making it a cost-effective solution for both car body shops and vehicle owners.

For steel panels, PDR offers an innovative and efficient way to handle various types of damage, from minor fender benders to more significant impacts. The technique is particularly advantageous in that it can be performed on-site at the car body shop, eliminating the need for lengthy paint jobs or extensive panel replacements. By leveraging the latest tools and techniques, PDR allows body shop services to provide swift and precise repairs, ensuring vehicles return to their pre-incident condition while maintaining their aesthetic appeal.

Benefits of Using PDR for Steel Panels

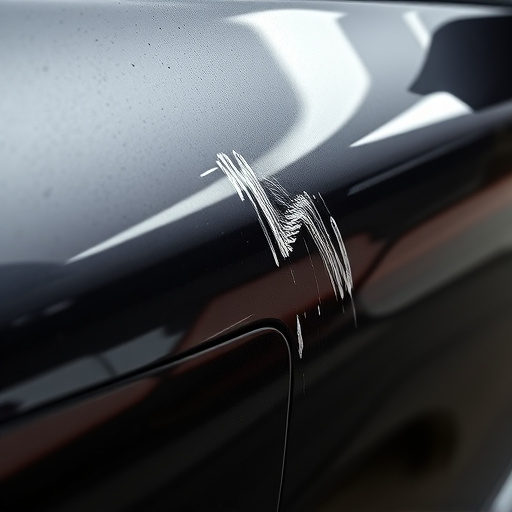

Using PDR for steel panels offers numerous advantages for both car owners and auto body shops. This non-invasive restoration technique is particularly beneficial for steel panel repairs, as it preserves the original factory finish while eliminating dents and scratches. Unlike traditional auto body services that may involve lengthy painting processes, PDR is an efficient method that can be completed in a fraction of the time, making it a preferred choice for those seeking swift yet effective solutions.

For car enthusiasts, such as those who own Mercedes Benz models, PDR presents an eco-friendly and cost-effective alternative to conventional repairs. By avoiding extensive repainting, this process reduces waste and minimizes the environmental impact commonly associated with auto body services. Moreover, PDR technicians can match the exact color of your steel panels, ensuring a seamless finish that blends in with the rest of your vehicle’s original design, much like how a gentle touch can restore a classic car to its former glory without disturbing its authentic character.

Real-World Success Stories: Customer Testimonials Unveiled

In the realm of automotive aesthetics and collision repair, PDR for steel panels has emerged as a game-changer. Real-world success stories, in the form of customer testimonials, highlight the transformative power of this innovative technique. Folks who have availed these services often find themselves captivated by the meticulous restoration of their car bodywork to near-perfect condition.

These testimonials paint a vivid picture, revealing how PDR effectively addresses various issues, from minor dents and dings to more severe collision damage. Many customers express satisfaction with the swift and efficient auto repair near them, underscoring the convenience and superior results offered by this cutting-edge method. Specifically, the ability of PDR to preserve the original factory finish and structural integrity of steel panels sets it apart from traditional repair methods, making it a preferred choice for car enthusiasts and those seeking top-tier collision repair services.

PDR for steel panels has proven to be a game-changer in the world of panel restoration, offering numerous benefits such as cost-effectiveness, minimal waste, and quick turnaround times. As evidenced by real-world success stories shared through customer testimonials, this revolutionary technique is transforming the way we think about panel repair. By adopting PDR, businesses can enhance their sustainability efforts, improve customer satisfaction, and restore damaged steel panels to like-new conditions, making it an indispensable tool for any maintenance or restoration project involving steel panels.