Computerized frame measurement systems transform automotive repair by providing accurate digital measurements, replacing manual methods and improving efficiency. They reduce turnaround times, enhance customer satisfaction, and ensure high-quality repairs. These tools streamline alignment, identify potential issues early, and save costs for shops and clients alike. Choosing the right software is critical, focusing on tailored needs, seamless integration with existing equipment, user-friendliness, and ongoing support from reputable providers.

Frame repair shops are embracing technological advancements with the investment in computerized frame measurement systems. This shift is revolutionizing the automotive industry, particularly in alignment and damage assessment. Computerized systems offer precise measurements, reducing manual errors and ensuring faster, more efficient repairs. In this article, we explore why adopting such technology is crucial for frame shops, highlighting its advantages and guiding them in selecting the right software to stay competitive in today’s market.

- Revolutionizing Frame Repair: The Need for Computerized Measurement

- Advantages of Computerized Systems in Automotive Alignment

- Choosing the Right Software: A Guide for Frame Shops

Revolutionizing Frame Repair: The Need for Computerized Measurement

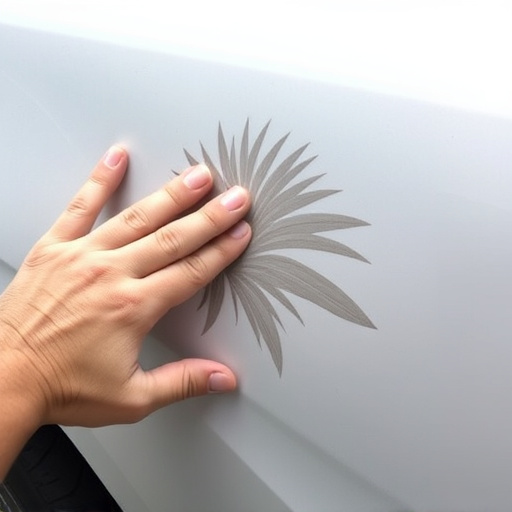

In the competitive landscape of automotive repair services, staying ahead means embracing technological advancements. One such game-changer in frame repair shops is the adoption of computerized frame measurement systems. This innovative approach revolutionizes how damage is assessed and repaired, moving away from traditional manual methods that can be time-consuming and prone to human error. With accurate, digital measurements, technicians can now swiftly diagnose issues, ensuring every vehicle dent repair is executed with precision.

Computerized frame measurement tools offer numerous benefits for both repair shops and customers. They streamline the process in collision centers, allowing for faster turnaround times without compromising quality. By leveraging technology, these advanced systems provide a new level of accuracy in car repair services, ultimately enhancing customer satisfaction and safety.

Advantages of Computerized Systems in Automotive Alignment

Computerized systems have revolutionized the automotive alignment process, offering numerous advantages for frame repair shops and vehicle body shops alike. One of the key benefits is precision; these advanced tools provide accurate measurements, ensuring that vehicles are aligned to the highest standards. This level of accuracy is particularly crucial when dealing with complex frame damage, as it allows technicians to make precise adjustments, resulting in better performance and handling.

Moreover, computerized frame measurement systems streamline the entire process, reducing the time typically required for manual alignment. This increased efficiency has a direct impact on business operations, enabling collision repair services to serve more customers without compromising quality. With real-time data and advanced algorithms, these systems also help identify potential issues early on, which can prevent further damage and reduce costs for both the shop and its clients, including those seeking auto glass repair services.

Choosing the Right Software: A Guide for Frame Shops

Choosing the right software is a pivotal step for frame shops looking to invest in computerized frame measurement tools. Key factors include considering the specific needs of the shop, whether it specializes in collision repair, bumper restoration, or offers comprehensive car paint services. Look for software that seamlessly integrates with existing equipment and provides accurate, detailed measurements for precise frame straightening – a critical aspect of any successful repair.

Additionally, user-friendliness is essential. Intuitive interfaces and training resources ensure technicians can quickly master the system, maximizing efficiency and reducing downtime. Reputable software providers often offer ongoing support and updates, which are crucial for keeping up with industry standards and technological advancements in frame repair, including innovative techniques like robotic welding and advanced paint matching algorithms.

Computerized frame measurement is no longer a luxury but an essential tool for modern frame repair shops. By embracing this technology, shops can streamline their processes, improve accuracy, and enhance customer satisfaction. With the right software in place, frame repair professionals can efficiently navigate the intricate world of automotive alignment, ensuring each vehicle leaves the shop with precise adjustments and a seamless ride. This investment in computerized systems is a game-changer, revolutionizing how we maintain and restore vehicles’ structural integrity.