High-Strength Steel (HSS) frames in luxury cars demand specialized frame repair technology for accurate, safe repairs meeting manufacturing standards. Laser and robotic welding, CAD, and 3D scanning enhance precision, efficiency, and durability, revolutionizing auto repairs while adhering to safety norms and promoting sustainable practices.

In today’s construction landscape, high-strength steel frames are revolutionizing building design. As these robust structures gain popularity, efficient frame repair technologies become essential for maintaining structural integrity. This article explores the innovative advancements in frame repair techniques specifically tailored for high-strength steel. We delve into the understanding of these unique frames, highlighting the benefits and wide-ranging applications of advanced frame repair technology, ensuring longevity and safety in construction projects.

- Understanding High-Strength Steel Frames

- Innovations in Frame Repair Techniques

- Advantages and Applications of Advanced Technology

Understanding High-Strength Steel Frames

High-Strength Steel (HSS) frames are a prevalent feature in modern automobiles, particularly in luxury vehicle repair and automotive restoration projects. These advanced frames are designed to withstand extreme forces, enhancing vehicle safety and structural integrity. HSS is characterized by its superior strength-to-weight ratio compared to traditional steel, making it a preferred material for manufacturers aiming to create lighter, yet robust vehicles. However, the unique properties of HSS also pose challenges during frame repair.

Frame repair technology specifically tailored for HSS frames is crucial in ensuring accurate and structural sound repairs. The process involves specialized techniques and tools to mitigate the risk of compromising the vehicle’s overall strength. Autobody repairs on HSS structures require precise alignment and welding procedures to maintain the material’s integrity, mimicking the original manufacturing standards. This advanced frame repair technology is essential for restoring the safety and performance of luxury vehicles, where precision and durability are paramount in every autobody repairs process.

Innovations in Frame Repair Techniques

The field of frame repair has witnessed significant advancements, driven by the evolving needs of the automotive industry. Modern vehicles, especially those from luxury brands like Mercedes-Benz, demand precision and strength in their construction, leading to the adoption of high-strength steel frames. This shift presents a unique challenge for collision repair technicians who must master innovative frame repair technologies tailored for these advanced materials.

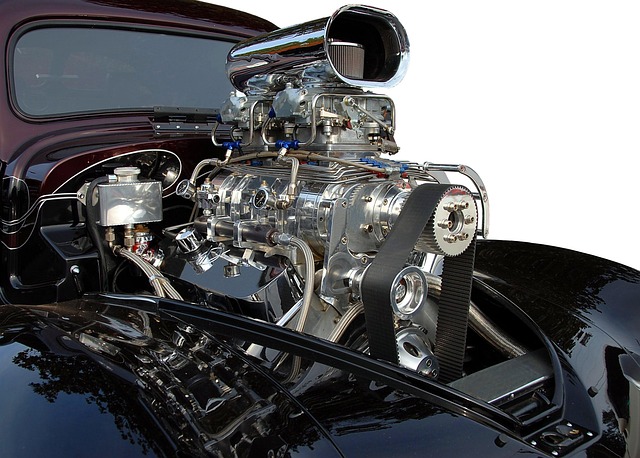

Techniques such as laser welding and robotic spot welding have become indispensable tools in modern frame repair shops. These methods ensure accurate, precise, and strong joints, crucial for maintaining the structural integrity of vehicles undergoing collision damage. Furthermore, advancements in computer-aided design (CAD) and 3D scanning enable detailed measurements and analysis, facilitating complex repairs with minimal distortion. This level of precision is essential in vehicle body repair and automotive restoration processes, ensuring that each component, from the frame to every panel, is restored to its original state or even enhanced for better performance and safety.

Advantages and Applications of Advanced Technology

Advanced frame repair technology offers a multitude of advantages for auto repair services, particularly when dealing with high-strength steel frames. One of the key benefits is its precision and efficiency in restoring structural integrity. This technology enables auto repair technicians to accurately assess and fix damaged components, ensuring vehicles meet safety standards. By employing advanced tools and methods, such as laser cutting and robotic welding, repairs are faster, cleaner, and more durable than traditional techniques.

The applications of this innovative frame repair technology span various types of vehicle damage, including hail damage repair and collision repair. It is especially valuable for modern cars with complex metal structures, where precise manipulation is crucial. Moreover, it streamlines the entire process, reducing labor costs and turnaround times without compromising on quality. This advanced approach to frame repair not only enhances the reliability of auto repair services but also contributes to more sustainable vehicle maintenance practices.

Frame repair technology has revolutionized high-strength steel frame repairs, offering advanced solutions for structural integrity. By leveraging innovative techniques and materials, professionals can now efficiently restore and reinforce these robust frames, ensuring longevity and safety in various applications. This cutting-edge approach to frame repair is a game-changer, providing permanent fixes and opening doors to enhanced architectural possibilities.