Aluminum panel dent repair requires a deep understanding of modern vehicle construction and advanced techniques to preserve structural integrity and aesthetics. Techniques include heat application, pneumatic tools, precision hand work, and cutting-edge technologies like laser repairs and robotic welding for intricate, accurate fixes, ensuring vehicles return to pre-accident condition with long-lasting results.

Aluminum panel dent repair is a precise science that involves understanding the unique structure and properties of these automotive panels. This article delves into the intricate world of repairing dents in aluminum bodies, exploring both traditional and advanced techniques. From comprehending the material’s behavior to mastering various repair methods, we’ll cover it all. Learn about the latest technologies revolutionizing the industry, ensuring optimal results for aluminum panel dent repair.

- Understanding Aluminum Panel Structure and Dents

- Common Dent Repair Methods: Techniques and Tools

- Advanced Technologies in Aluminum Panel Restoration

Understanding Aluminum Panel Structure and Dents

Aluminum panels used in modern vehicles are designed for lightweight and durability, but they’re not immune to dents and dings. Understanding the structure of these panels is key to effective aluminum panel dent repair. These panels consist of a thin layer of aluminum bonded to a steel core, often with a protective coating for enhanced resistance to corrosion. When a dent occurs, it can deform the aluminum surface while minimizing damage to the underlying materials.

Proper evaluation is crucial before initiating any repair process. Technicians use specialized tools to assess the depth and extent of the dent, determining whether it affects structural integrity or merely causes cosmetic issues. The goal of aluminum panel dent repair is not just to restore the exterior aesthetics but also to maintain the vehicle’s overall safety and performance, making it a precise art that requires skilled hands and advanced techniques, often facilitated by car paint services for a seamless finish, much like auto repair near me centers offer.

Common Dent Repair Methods: Techniques and Tools

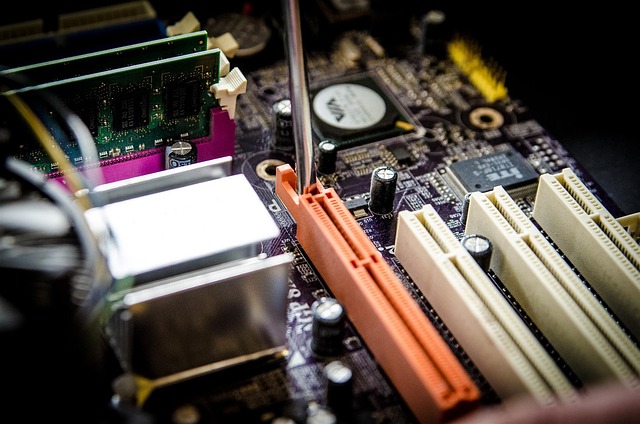

In the realm of aluminum panel dent repair, several techniques and tools have emerged to address common issues encountered in auto repair shops. One widely used method involves the application of heat, which can be achieved through specialized tools like heat guns or air compressors. By carefully directing heated air, technicians can gently expand the metal, allowing it to return to its original shape without causing further damage. This technique is particularly effective for shallow dents and is often a go-to method in Mercedes Benz collision repair.

Another prevalent approach is the use of pneumatic tools, such as dent pullers or pry bars, which leverage air pressure to pop out depressed panel areas. These tools are versatile and can handle various dent sizes, making them a valuable asset in any auto repair shop. For more intricate repairs, professional technicians might employ precision-cut templates and hand tools to carefully extract and replace damaged panels, ensuring a flawless finish akin to that of a car scratch repair.

Advanced Technologies in Aluminum Panel Restoration

The world of aluminum panel dent repair has witnessed a significant evolution, driven by advanced technologies and the demand for efficient collision repair services. Modern auto body shops are now equipped with innovative tools that enable precise restoration, ensuring vehicles look as good as new. One such technology is laser-based repair systems, which offer incredible accuracy in detecting and correcting dents. This non-invasive method minimizes damage to the panel, preserving its original integrity.

Additionally, robotic welding machines have revolutionized the process, allowing for faster and more consistent repairs. These robots can handle intricate shapes and curves with ease, making them ideal for complex aluminum panel dent repair jobs. As collision centers strive to provide top-notch services, embracing these advanced technologies ensures customers receive high-quality, long-lasting repairs, restoring their vehicles’ pre-accident condition.

Aluminum panel dent repair is a precise science that combines understanding material properties with advanced technologies. By mastering both traditional and innovative techniques, professionals can restore damaged panels to their original condition, ensuring vehicles maintain their aesthetic appeal and structural integrity. As the automotive industry continues to evolve, ongoing research and development in aluminum panel restoration will play a vital role in meeting the growing demand for efficient, effective, and eco-friendly repair solutions.