The evolution of collision repair services has transformed a once cumbersome process into a precise science, driven by advanced tools like automated metal forming machines, digital design software (e.g., CAD), and 3D printing. These innovations ensure high-quality, efficient repairs with faster turnaround times, as collision repair centers adopt cutting-edge systems to meet customer demands. Modern technology reduces vehicle downtime, improves outcome quality, and promotes sustainability in the industry.

Collision repair services have undergone a remarkable transformation driven by technological advancements. From manual processes to modern marvels, today’s collision repair centers are hubs of innovation. This article explores the advanced training behind these cutting-edge services, tracing the evolution from historical practices to the latest digital and sustainable trends. We delve into the crucial role of technology, interactive training methods, and game-changing innovations like 3D printing and AI automation, shaping the future of collision repair.

- The Evolution of Collision Repair Technology

- – A historical perspective on collision repair

- – Introduction of modern tools and equipment

The Evolution of Collision Repair Technology

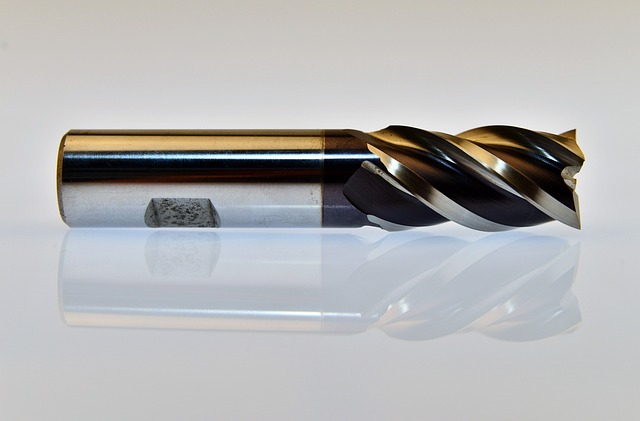

The evolution of collision repair technology has been nothing short of remarkable, transforming what was once a tedious and time-consuming process into a sophisticated science. Modern collision repair services now leverage advanced tools and techniques that were unimaginable just a few decades ago. Automated metal forming machines, for instance, streamline the panel replacement process, ensuring precision and consistency in car body restoration.

Digital design software and 3D printing have also revolutionized vehicle collision repair. These innovations allow for complex repairs to be planned and executed with unparalleled accuracy, reducing waste and enhancing overall efficiency. As technology continues to advance, collision repair centers are staying ahead of the curve by adopting cutting-edge systems, ensuring they provide the best possible services to their customers in terms of both quality and turnaround time.

– A historical perspective on collision repair

Collision repair services have evolved significantly over the years, transforming from simple, often makeshift, repairs to a highly advanced and specialized field. Historically, auto body shops would handle collision repairs using basic tools and techniques, with much of the work done by hand. Repairs were typically focused on structural integrity, primarily straightening frames and replacing damaged panels. The process was labor-intensive, time-consuming, and often left room for error.

With advancements in technology and safety standards, collision repair services have become more sophisticated. Modern auto body shops now employ advanced equipment like robotic welding machines, computer-aided design (CAD) software, and precision measuring tools to ensure accurate and efficient repairs. These innovations not only enhance the quality of fender repair but also reduce the time it takes to get a vehicle back on the road. Additionally, environmental considerations have led to the adoption of eco-friendly practices and materials in auto repair services, further revolutionizing the industry.

– Introduction of modern tools and equipment

The evolution of collision repair services is largely driven by the introduction and refinement of modern tools and equipment. Today’s collision repair shops are no longer reliant solely on manual labor and traditional methods; they harness the power of advanced technology to enhance efficiency, accuracy, and safety. This transformation has been instrumental in raising industry standards, ensuring car body restoration that meets or exceeds original manufacturer specifications.

From computer-aided design (CAD) software for precise measurements and 3D imaging to robotic welding systems that offer unparalleled consistency and speed, modern tools have revolutionized the way automotive repair is carried out. These innovations not only streamline the repair process but also contribute to reduced downtime for vehicle owners, higher quality outcomes, and more sustainable practices within collision repair shops.

Modern collision repair services have undergone a remarkable transformation, driven by advanced training and innovative technology. The evolution from traditional, manual methods to state-of-the-art practices has significantly improved efficiency and precision in the industry. By leveraging modern tools and equipment, skilled technicians can now offer more effective, safer, and environmentally conscious collision repair solutions. This advancement not only benefits businesses but also ensures that vehicles return to the road in better condition, enhancing safety and sustainability for all road users.