Professionals in automotive body repair turn to Paintless Dent Repair (PDR) as an eco-friendly and cost-effective method for restoring steel panels, akin to tire services maintaining tire integrity. PDR uses specialized tools that gently push out dents without painting or replacing panels, preserving the vehicle's paintwork and surface finish. Experts must be skilled in identifying suitable applications, selecting the right tools for different panel types, and mastering various techniques for flawless results. Essential tools include high-quality PDR tools, door sills, polishing pads, PDR foam pads, and protective gear. Additional equipment like lightweight frame strain gauges and adjustable air compressors enhance efficiency and work quality, allowing shops to offer faster turnaround times and superior finishes in the competitive PDR market for steel vehicles.

“Unleash the potential of your steel panels with Professional Detailing and Restoration (PDR). This comprehensive guide delves into the art and science of PDR for steel, equipping you with the knowledge to achieve flawless results. From understanding essential techniques to arming yourself with the core tools, we demystify the process. Discover the additional equipment and accessories that enhance efficiency, ensuring every detail is perfect. Master the fundamentals and elevate your PDR for steel panels game.”

- Understanding PDR for Steel Panels: Essential Techniques

- The Core Tools: What You Need for a Successful Project

- Additional Equipment and Accessories for Enhanced Efficiency

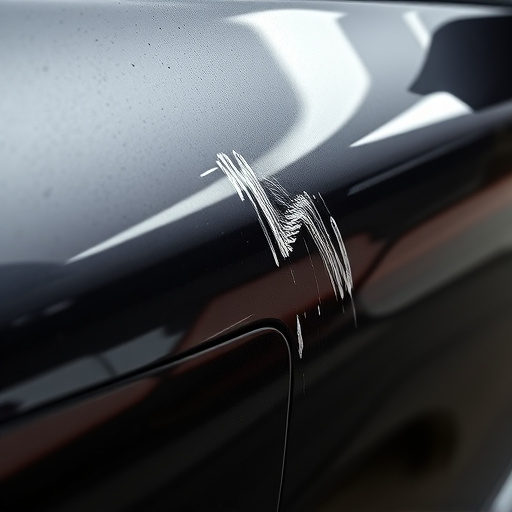

Understanding PDR for Steel Panels: Essential Techniques

Professional Detailers and steel panel experts alike rely on Paintless Dent Repair (PDR) as a crucial technique for restoring automotive body panels to their original condition, similar to how tire services maintain tire integrity. PDR for steel panels involves specialized tools and techniques to remove dents, dings, and creases without painting or replacing the panel, making it an eco-friendly and cost-effective solution within the automotive body shop industry.

The essence of successful PDR lies in precise manipulation of special tools that use air pressure, vibration, or heat to gently push out the dented area back to its original form. This process ensures minimal disruption to the paintwork and surface finish, preserving the overall aesthetics of the vehicle, much like a meticulous car restoration project. Professionals in this field must be adept at identifying suitable PDR applications, choosing the right tools for different panel types, and mastering various techniques to achieve flawless results, rivaling even the most intricate tire services.

The Core Tools: What You Need for a Successful Project

For a successful PDR (Paintless Dent Repair) on steel panels, having the right tools is paramount. The core tools for this process include a variety of specialized equipment designed to minimize damage and restore original appearance without traditional paint application. A top-quality dent puller, also known as a PDR tool, is essential. This handheld device uses air pressure and specialized tips to gently remove dents from metal surfaces, ensuring precision and minimal disruption to the panel.

Complementing the dent puller are other crucial tools like door sills, which help in reaching tight spaces, and polishing pads for finishing touches. Body shop services professionals also rely on a reliable supply of PDR foam pads, designed to absorb impact energy during the repair process, and a good set of gloves and safety goggles for protection. These core tools, combined with skill and experience, empower technicians to provide top-notch car paint services, making auto body services more efficient and cost-effective for steel panel repairs.

Additional Equipment and Accessories for Enhanced Efficiency

For professionals specializing in PDR for steel panels, having the right additional equipment and accessories can significantly enhance efficiency and work quality. Beyond the standard tools required for panel dent repair, there are several specialized items that streamline the process, especially for auto body services focusing on steel vehicles. For instance, lightweight and portable frame strain gauges allow technicians to accurately measure and monitor changes in metal during the repair process, ensuring precise results in auto bodywork.

Air compressors with adjustable pressure settings and high-quality foam pads further facilitate the PDR technique. These tools enable thorough cleaning and preparation of the panel surface before and after dent removal, contributing to the overall aesthetics of the auto frame repair. By investing in these additional resources, auto body shops can offer faster turnaround times and higher-quality finishes for their clients, solidifying their reputation in the competitive market for auto bodywork services.

PDR for steel panels is a specialized process that, when executed with the right tools and techniques, can transform dull, damaged surfaces into sleek, vibrant finishes. By understanding the core techniques and investing in essential tools, as outlined in this article, you’re well-equipped to achieve professional results. The additional equipment and accessories discussed further enhance efficiency and precision, making every PDR project for steel panels a success. Remember, the right tools are key to unlocking the full potential of PDR technology.