OEMs maintain peak vehicle structural integrity and driver safety through strict frame repair safety standards, utilizing Service Bulletins as a strategic tool. These bulletins provide detailed procedures and best practices, ensuring compliance with stringent norms and minimizing risks of subpar repairs. By offering clear guidelines on alignment and welding, they facilitate quality control in auto body shops, building trust among OEMs, facilities, and vehicle owners. While effective communication and continuous updates are challenges, Service Bulletins significantly enhance the safety and quality of dent repair processes.

Original Equipment Manufacturers (OEMs) prioritize passenger safety by enforcing stringent frame repair safety standards. This article delves into the significance of these standards and how OEMs utilize Service Bulletins as a crucial tool for their implementation. We explore the benefits, such as enhanced structural integrity, and challenges faced when adopting these guidelines. By understanding the impact of frame repair safety standards, auto industry professionals can grasp why adherence to OEM-issued bulletins is vital for maintaining vehicle safety and reliability.

- Understanding Frame Repair Safety Standards: Why They Matter for OEMs

- Service Bulletins: The Tools OEMs Use to Enforce Safety Standards

- Benefits and Challenges of Implementing Frame Repair Safety Standards Through Service Bulletins

Understanding Frame Repair Safety Standards: Why They Matter for OEMs

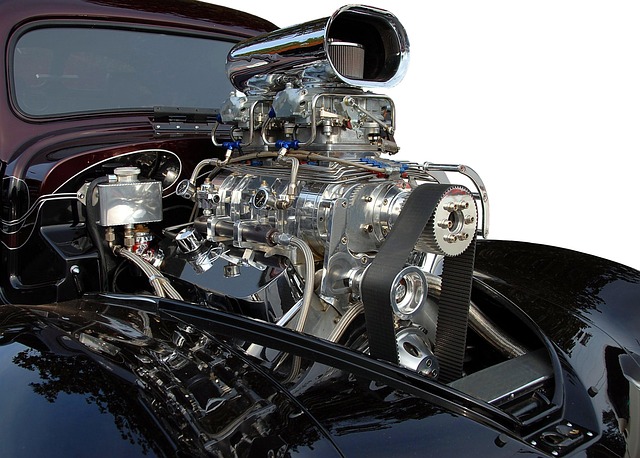

OEMs (Original Equipment Manufacturers) produce vehicles that are held to the highest quality and safety standards. Understanding and enforcing frame repair safety standards is a critical aspect of this, especially when it comes to post-collision repairs. These standards ensure that any structural damage to a vehicle, often sustained in accidents, is properly assessed and repaired, maintaining the overall safety and integrity of the automobile.

Frame repair safety standards play a vital role in ensuring not only the safety of drivers but also the effectiveness of collision repair processes. Proper adherence to these guidelines by both manufacturers and service centers guarantees that vehicles return to their pre-accident condition. This is achieved through meticulous techniques, utilizing advanced equipment for frame alignment and precise car paint services, followed by thorough quality checks to confirm the structural soundness of every restored vehicle. The ultimate goal is to facilitate safe driving conditions while preserving the aesthetics and value of the automobile through comprehensive car body restoration processes.

Service Bulletins: The Tools OEMs Use to Enforce Safety Standards

Original Equipment Manufacturers (OEMs) leverage Service Bulletins as a powerful tool to enforce frame repair safety standards across their vehicle fleets. These bulletins serve as comprehensive guidelines, detailing specific procedures and best practices for auto frame repair, ensuring adherence to stringent industry norms. By disseminating such information, OEMs actively mitigate potential risks associated with substandard frame repairs, which could compromise vehicle safety and structural integrity.

Service Bulletins play a pivotal role in maintaining the highest levels of quality control within automotive repair shops. They provide detailed instructions on everything from alignment techniques to welding protocols, empowering technicians to conduct meticulous auto frame repairs. This proactive approach not only safeguards consumer safety but also fosters trust between OEMs, repair facilities, and vehicle owners by promoting transparent and reliable auto body work practices.

Benefits and Challenges of Implementing Frame Repair Safety Standards Through Service Bulletins

Implementing frame repair safety standards through Service Bulletins offers numerous benefits for Original Equipment Manufacturers (OEMs) and their customers alike. These bulletins provide a clear, centralized source for disseminating critical information related to auto body restoration and specific frame repairs. This ensures that authorized service centers and mechanics across the industry are equipped with the latest guidelines, enhancing the overall safety and quality of auto dent repair processes. By mandating adherence to these standards, OEMs can mitigate risks associated with substandard repairs, leading to improved vehicle structural integrity and passenger safety.

However, there are challenges in this approach. Effective communication is paramount, as mechanics must promptly access and understand these bulletins. Ensuring widespread adoption and compliance across diverse service centers could be difficult, especially in regions with limited internet connectivity or where auto repair services are less standardized. Additionally, the continuous evolution of safety standards requires OEMs to regularly update Service Bulletins, demanding a dynamic and efficient communication system.

OEMs play a vital role in ensuring vehicle safety by implementing frame repair safety standards through service bulletins. These guidelines provide a structured approach to repairing damaged frames, minimizing risks and maintaining structural integrity. While there are challenges in dissemination and adherence, the benefits of enhanced safety, improved quality control, and customer trust make this method an essential tool for the automotive industry. By continuously updating and promoting these standards, OEMs contribute to overall road safety.