PDR (Paintless Dent Repair) techniques offer a sustainable solution for car repair, minimizing material waste, chemical emissions, and energy consumption compared to traditional methods. By gently reshaping outer panels without cutting or replacing parts, PDR preserves the car's original structure and reduces environmental impact. This eco-friendly approach not only cuts down on scrap materials but also promotes sustainability in the automotive repair industry, appealing to environmentally conscious customers and enhancing a company's public image as an eco-leader.

Discover the eco-friendly benefits of Professional PDR (Paintless Dent Repair) techniques, a revolutionary approach to vehicle damage restoration. This article explores how PDR minimizes waste and environmental impact by reducing material usage, enhances energy efficiency through sustainable practices, and drives long-term cost savings for businesses adopting this green model. By embracing PDR techniques, the automotive industry can contribute to a more sustainable future.

- Reducing Waste and Environmental Impact: How PDR Minimizes Material Usage

- Energy Efficiency and Sustainable Practices in PDR Processes

- Long-Term Cost Savings and Eco-Friendly Business Model Transformation

Reducing Waste and Environmental Impact: How PDR Minimizes Material Usage

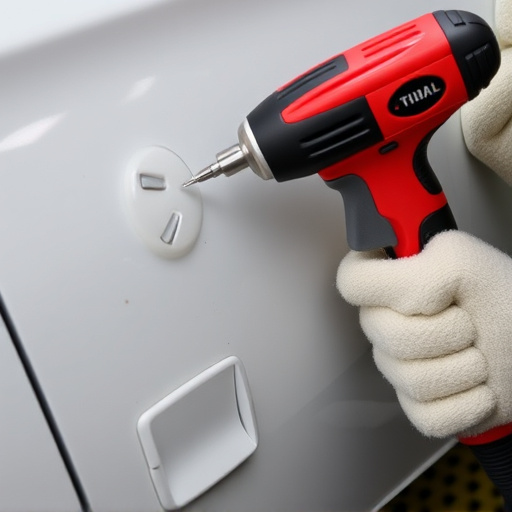

PDR techniques, or Plastic Deformation Repair, offer a highly effective method for restoring damaged cars without the need for extensive auto painting or frame straightening. By utilizing specialized tools to gently push and pull the car’s outer panels back into their original shape, PDR minimizes material damage and waste. This eco-friendly benefit is significant in reducing the environmental impact of automotive repairs.

Traditional methods often involve cutting and replacing damaged parts, leading to increased scrap materials and a higher carbon footprint. In contrast, PDR techniques promote sustainability by preserving the existing car body structure, thereby decreasing the demand for new materials and resources. This not only cuts down on waste but also saves energy and reduces greenhouse gas emissions associated with manufacturing and transportation of auto painting and replacement parts.

Energy Efficiency and Sustainable Practices in PDR Processes

The adoption of PDR techniques (Paintless Dent Repair) in collision repair centers and car bodywork services has brought about a significant shift towards energy efficiency and sustainable practices. Unlike traditional car paint services, PDR minimizes material waste by eliminating the need for sandpaper or harsh chemicals, which reduces the environmental footprint of the process. By preserving the original factory finish on vehicles, these techniques also cut down on energy-intensive repainting processes, further enhancing sustainability.

In addition, PDR centers often employ advanced tools and equipment that are designed to be more energy-efficient than conventional methods. This includes the use of specialized air compressors and temperature-controlled tools, which reduce energy consumption during repairs. As a result, collision repair facilities can offer eco-friendly car bodywork services while still maintaining high-quality outcomes, contributing to a greener automotive industry overall.

Long-Term Cost Savings and Eco-Friendly Business Model Transformation

Adopting PDR techniques (paintless dent repair) offers long-term cost savings for businesses and contributes to a significant eco-friendly transformation in the automotive industry. Traditional car body repair methods often involve extensive use of materials, energy, and chemicals, leading to higher operational costs and environmental impact. In contrast, PDR is a minimally invasive process that focuses on restoring vehicle bodywork to its original condition without painting, thus reducing material waste and chemical emissions.

This shift towards PDR techniques aligns with the growing trend of sustainable business models in the automotive sector. By minimizing the use of harmful substances and streamlining repair processes, businesses can lower their carbon footprint while achieving efficient long-term cost savings. This dual benefit not only attracts environmentally conscious customers but also positions businesses as leaders in eco-friendly car body repair, fostering a positive public image and contributing to a greener future.

Professional dent repair (PDR) techniques offer a compelling path towards a greener future for the automotive industry. By minimizing waste, reducing energy consumption, and fostering long-term cost savings, PDR not only benefits businesses but also contributes to a sustainable environment. Adopting these eco-friendly practices is a win-win, ensuring a cleaner, more efficient, and responsible approach to vehicle restoration.