Precision frame alignment is a meticulous auto repair process that uses laser scanners and specialized software to restore a vehicle's structural integrity after accidents or wear and tear, enhancing handling, ride quality, and reliability. The procedure, ranging from 1-2 hours for minor issues to over 6 hours for severe cases, is influenced by environmental factors. Auto body shops optimize efficiency through proper vehicle preparation, advanced tools like modern frame straightening machines, and a systematic alignment approach to ensure cost-effectiveness and quick turnaround times.

Discover the ins and outs of precision frame alignment—a critical process ensuring your equipment operates at peak efficiency. This in-depth guide explores how long it typically takes, delving into the factors influencing alignment duration and offering expert strategies to optimize efficiency. Whether you’re an industry professional or a novice, understanding these insights can significantly impact your workflow, making precision frame alignment a seamless and swift process.

- Understanding Precision Frame Alignment: The Process Unveiled

- Factors Influencing Alignment Time: A Detailed Look

- Optimizing Efficiency: Strategies to Reduce Alignment Duration

Understanding Precision Frame Alignment: The Process Unveiled

Understanding Precision Frame Alignment: The Process Unveiled

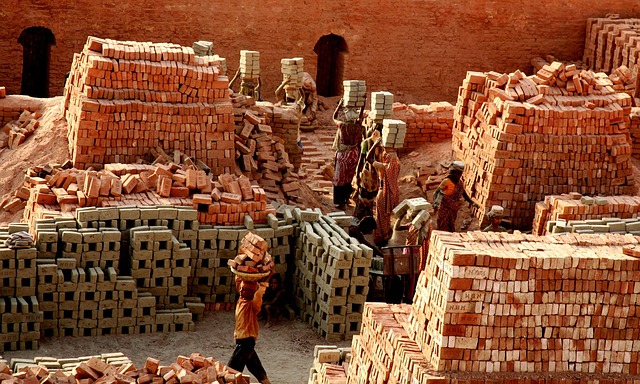

Precision frame alignment is a meticulous process that involves realigning a vehicle’s structural components to their original factory-specified positions. This intricate procedure is crucial in ensuring the safety, stability, and overall performance of a car after it has experienced damage from accidents or routine wear and tear. The process begins with a thorough inspection using advanced technology, such as laser scanners, which capture precise measurements of the vehicle’s frame and body panels.

These measurements are then fed into specialized software that calculates the exact adjustments needed to bring the frame back into alignment. Technicians employ sophisticated equipment like hydraulic presses and computer-controlled jacks to make these minute adjustments. The goal is not just to restore the car to its pre-damage condition but also to minimize future issues related to handling, ride quality, and structural integrity. This meticulous auto detailing process forms a vital component of automotive collision repair, ensuring that vehicles return to their optimal state, much like a damaged painting is restored to its original beauty through skilled artistry, with each adjustment a brushstroke towards perfection.

Factors Influencing Alignment Time: A Detailed Look

The duration of precision frame alignment can vary greatly depending on several factors unique to each vehicle and its condition. While some processes may take a few hours for lighter repairs or routine maintenance, more complex cases involving severe car damage repair, vehicle restoration, or structural adjustments could extend the timeline significantly.

For instance, a mercedes benz repair with minimal frame misalignment might be swiftly resolved within an hour or two. Conversely, a vehicle with substantial damage requiring intricate metalwork and precise adjustments can easily consume 4-6 hours or more. Moreover, environmental conditions also play a role; colder temperatures can slow down the alignment process due to the need for warmer materials to achieve accurate measurements, whereas humid climates may necessitate additional drying time between steps.

Optimizing Efficiency: Strategies to Reduce Alignment Duration

Optimizing efficiency is a key aspect when it comes to precision frame alignment, as every minute saved translates to cost-effectiveness and faster turnaround times for auto body shops offering these services. There are several strategies that can help reduce the duration of this critical process. One of the most effective methods is preparing the vehicle properly before alignment. This includes removing all loose debris, checking for any obvious damage or misalignments, and ensuring the wheels are in their correct positions. A thorough pre-alignment inspection can significantly streamline the subsequent adjustments.

Additionally, utilizing advanced tools and equipment can dramatically enhance efficiency. Modern frame straightening machines often come with sophisticated sensors and computer controls that enable precise measurements and quick adjustments. Keeping these systems well-maintained and up-to-date ensures optimal performance. Another strategy is to employ a systematic approach to alignment, breaking down the process into manageable steps rather than attempting to correct all issues at once. This methodical procedure not only saves time but also minimizes the risk of errors during auto frame repair or car damage repair processes.

Precision frame alignment, a meticulous process, typically requires 2-4 hours, depending on various factors. By optimizing strategies like advanced technology adoption, regular maintenance checks, and efficient workflow management, this duration can be significantly reduced. Understanding these influences empowers professionals to streamline operations, ensuring faster turnaround times without compromising accuracy in the intricate world of precision frame alignment.